Power Enhancement Technologies

Baltect IES provides a range of gas turbine power enhancement solutions which can be applied to any gas turbine opearating in any location in the world.

OptiMist Systems

A cost effective solution for boosting power in climates with low humidity levels

OptiMist systems work on the traditional fogging principle, where a fine mist of water is sprayed within the intake duct of the gas turbine which quickly evaporates prior to reaching the compressor intake. The evaporation of the water causes a reduction of air temperature and an increase of mass flow into the compressor.

Benefits that Optimist technology can deliver:

- Up to 10% boost in power (Depending on ambient humidity levels)

- Up to 2% gain in efficiency (Depending on ambient humidity levels)

- Exceptionally short system start time

- Simple installation within existing plant outage windows.

- Low capital cost solution

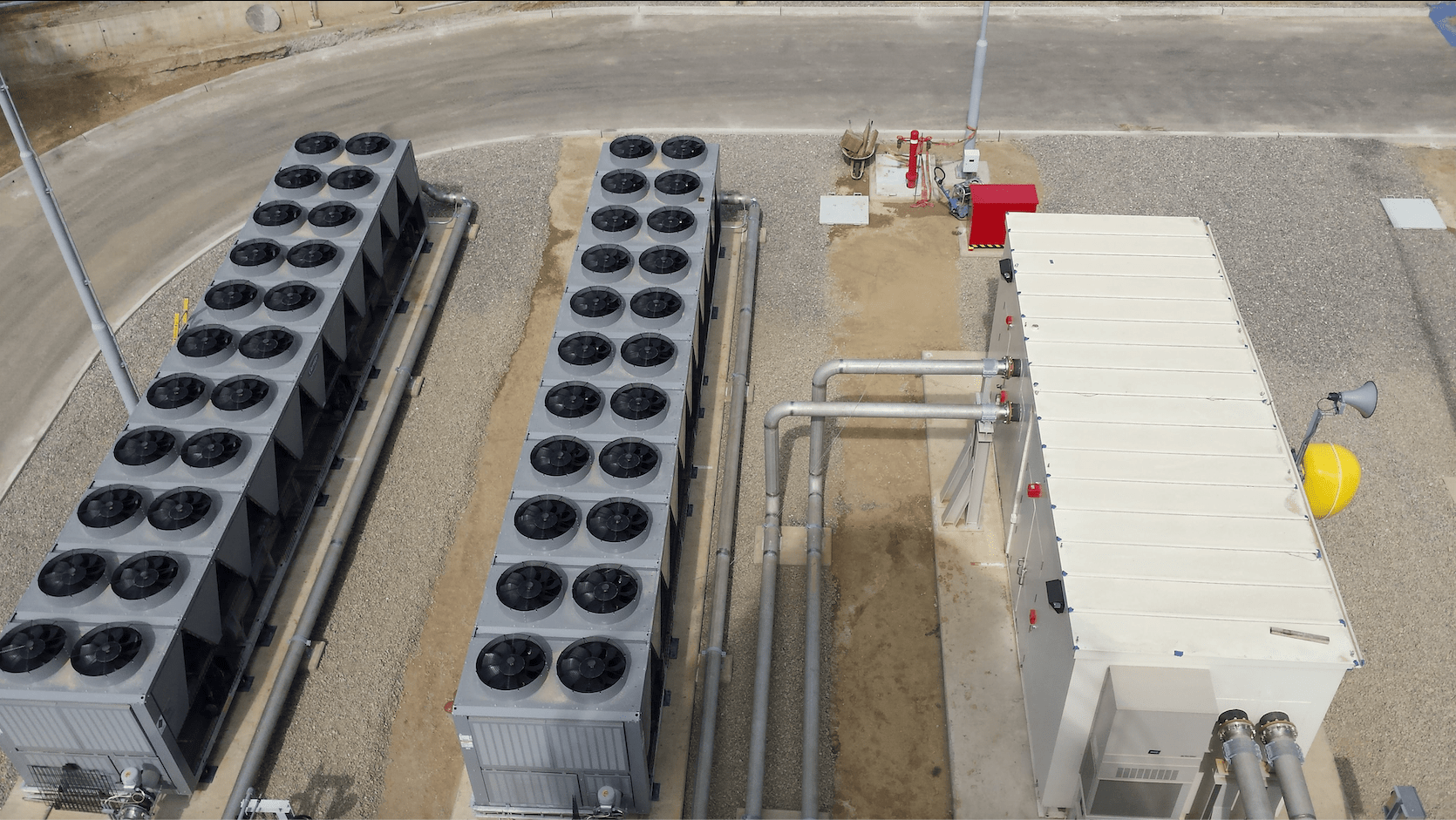

Echill Systems

A solution which delivers consistent power gains in any climate

Benefits that Echill technology can deliver:

- Up to 20% boost of power

- Consistent performance in any ambient conditions (subject to chiller capacity)

- No water use if dry heat exchangers used for chiller cooling

- Implementation with Thermal Energy Storage to improve system efficiency

OptiFlash Systems

An innovative and simple approach delivers consistent power gains and reduces emissions by only using water

OptiFlash is an innovative wet compression technology which uses hot pressurised water to spray incredibly fine droplets into the compressor through the use of specially designed nozzles. These fine water droplets evaporate inside of the compressor, increasing mass flow through the turbine and reducing the compressor discharge temperature. This ultimately results in impressive power gains and significant reductions of NOx emissions.

Benefits that OptiFlash technology can deliver:

- 20 to 40% reduction in NOx emissions (depending on combustor design)

- Up to 15% boost of power

- Up to 3% gain in efficiency (Depending on ambient humidity levels)

- Hot component life extension due to reduced cooling air temperatures

- Exceptionally short system start time – suitable for power reserve applications

- Simple installation within existing plant outage windows

- Very low maintenance

Comparison

Below is a side by side comparison of the performance of the 3 technologies for two different temperature/humidity combinations.

Enquiry Form

Baltec IES Pty. Ltd.

Head Office

Notting Hill, Melbourne

Victoria 3168, Australia